What is a PCB? Where are the PCB boards used?

Where is the position of the PCB?

Almost all electronic devices have PCB board. They are green, red, blue or black. The computer motherboard is a perfect example of a PCB.

They are found in everyday appliances such as printers, digital clocks, televisions, microwave ovens and even simple items such as light switches.

Without a series of reliable PCBs, our society will run on PCBs, and families and businesses cannot run smoothly right now. In fact, commercial buildings often contain more PCBs than the number of employees.

So let’s find out what PCBs are and provide more insight.

What is a PCB?

Printed circuit boards (PCBs) are convenient thin plates for accommodating interconnected electrical components in a simple, convenient, and economical manner. They are used as physical supports to install and connect different electrical components.

PCB is made of glass fiber, composite epoxy resin or any other composite material with metal coating surface. They have etchings made of metal and acid to create circuits that pass through different integrated circuits (IC) and other components on the circuit board. Solder connects the IC and other components to the surface of the circuit board.T he copper track in the circuit board reduces the possibility of short-circuiting, misaligned or misaligned wires.

In this way, all components are firmly fixed to the circuit board without complex wiring systems and unnecessary costs. This also simplifies the process of maintaining the PCB according to your requirements-without having to deal with a lot of wires.

However, standard PCBs are not used in all electrical applications. In fact, they vary according to the size, shape and function of the electronic device. For example, the type of PCB used in a smartwatch is different from the type used in a TV.

Now let’s look at the different products in the PCB.

Flexible Printed Circuit Board

What is the product of PCB?

PCBs can almost be found in some form of electronic device. Below I share some common types of devices where you can find PCBs.

Consumer electronics-this includes all the electronics we use in our lives. From audio and video systems, TVS, video and DVD players, digital cameras, computers and laptops, mobile phones and GPS to home and kitchen appliances. These devices often use standard PCBs that are quite standard and similar to each other.

Medical devices – high density PCBs can be used for medical devices. They support the use of more intensive design to test new and advanced medical technologies. It also reduces the complexity of making small, lightweight medical devices.PCBS are suitable for medical devices of all sizes, from small pacemakers to large X-ray and CAT machines.

Industrial machinery – PCBs are commonly used in high power industrial machinery. Thick copper PCBs are commonly found in industrial machinery to better meet important requirements. For example, thick copper PCBs can be found in industrial machines such as motor controllers, industrial load testers and high-current battery charging.

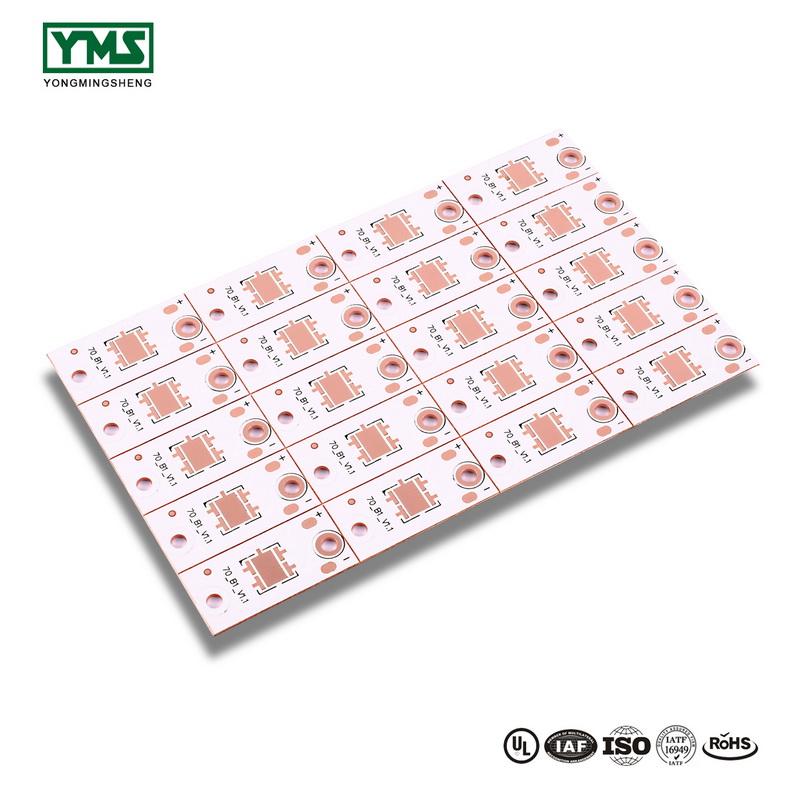

LED applications – LED lighting is another common PCB device, which is a more modern form of technology but is still primarily based on PCB, which is known for increasing power consumption. LED lamps have PCBs that act as radiators, allowing a higher level of heat transfer than normal PCBs. Even some other basic lighting solutions use these aluminum backplates for high levels of heat transfer.

Automotive and aerospace related equipment – PCBs are designed to withstand high vibration environments and can be used in automotive and aerospace industry related equipment. Flexible PCBs support the vibration characteristics of these industries. They can be very flexible and can accommodate very small spaces designed inside the device. The PCBs in these devices can also be very lightweight and durable, which is essential for manufacturing transportation components and industries with high impact, low weight requirements.

I hope this helps you learn more about where to find PCBs. Basically, they can be seen everywhere in our daily life. So let’s see what it actually does.

What functions does PCB execute

The primary function of the PCB is to accommodate and facilitate the smooth flow of current between the required connecting elements, which are built into the PCB. However, for a better understanding, here are a few other different operations of the PCB.

Resistance – controlling the current is important for most appliances to avoid burning out. For this reason, the resistance of the PCB can resist the current flow according to its value.

Distribution – as mentioned above, PCBs can be assembled easily. For this reason, the PCB pad is empty. When required, these pads allocate space so that any other electronic components can be easily welded.

Assembly – for ease of assembly, the PCB also has some words called “screen printing”. These help identify the exact location of the part and its location by letter.

Storage – used to store power supply PCBs can hold capacitors. These help keep charging and release power when needed.

Signals pass through lights – PCBs have small bulbs like diodes that light up to show the current passing through.

Switch used to control – PCB house switch can control the excessive current between different components.These also help regulate the heat affecting the circuit board layer.

In addition to these well-designed operations, PCBs can be better adapted and adapted to any device. Let’s see how it goes!

How to mold PCBs to suit device type

The overall popularity of the PCB is due to its applicability to almost any product. Here are several types of PCBs that will show you how to shape them to better fit any device they design.

Rigid PCB

These PCBs are manufactured PCBs made of strong materials that can be bent or twisted. They are very complex and strong, and have strong circuits around them.

They are easy to handle during repair and maintenance because they are robust and can withstand powerful operations. In addition, the components labeled on the board are generally clearer and the signal paths are well organized.

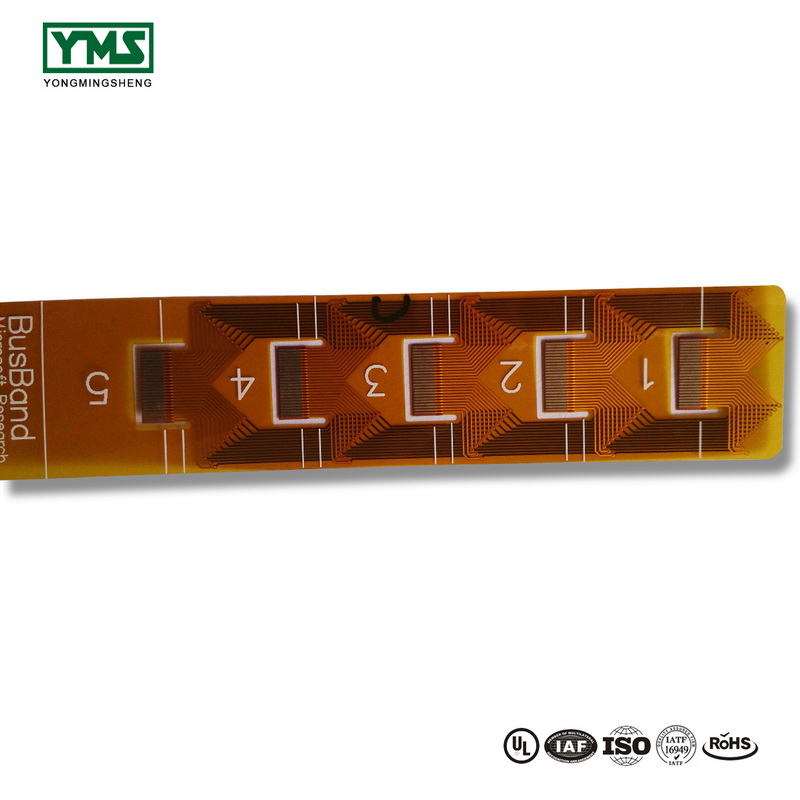

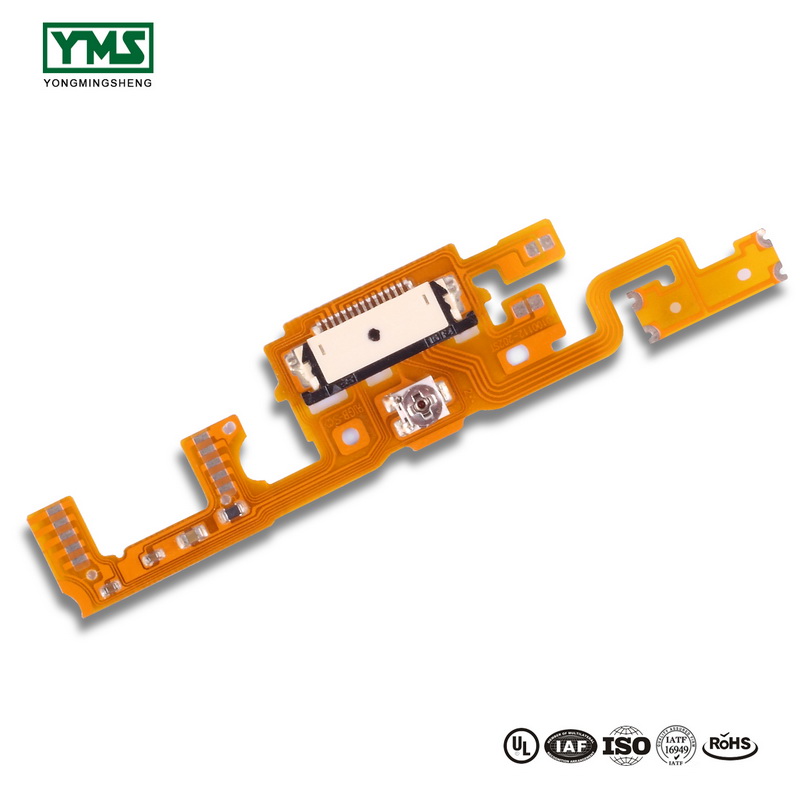

Flexible PCB

As the word says, these PCBs are very flexible and make flexible materials in the same way. Flexible PCBs can be single-layer, double-layer and multi-layer. This design facilitates easy assembly of parts in small or fragile devices. Flexibility also helps save a lot of space and is lightweight in the device. These PCBs are best suited for temperature-sensitive working conditions or industries and related equipment.

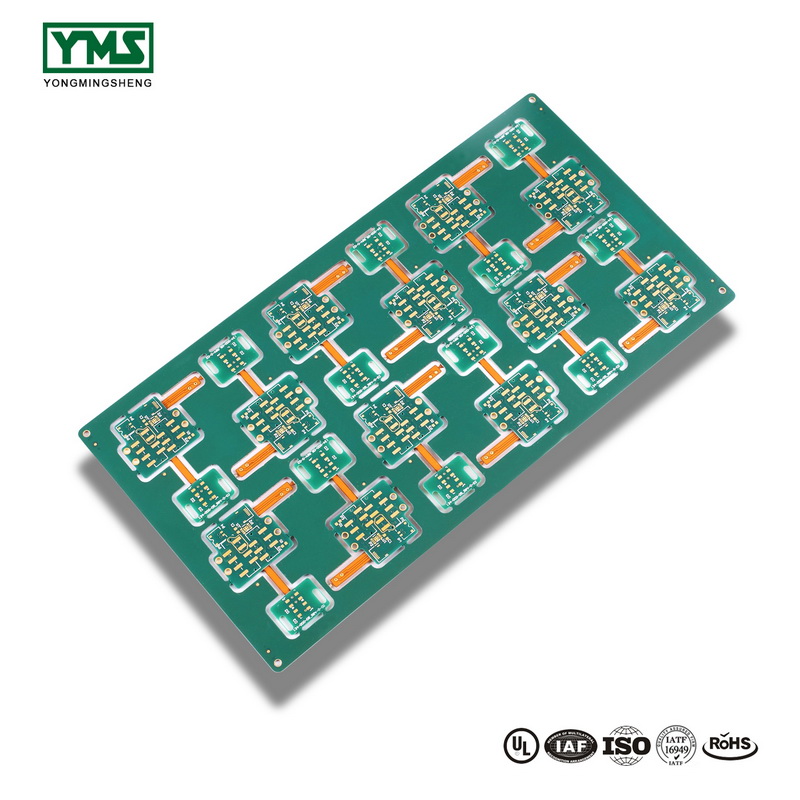

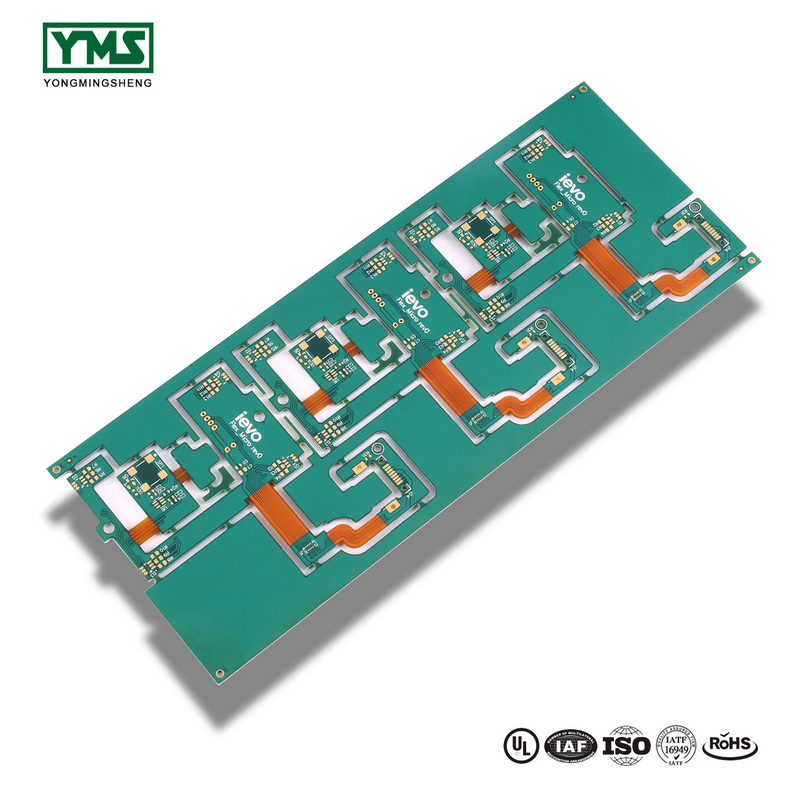

It Rigid – Flex PCBs

These boards are a combination of rigid and flexible PCBs. These types of PCBs use multi-layer flexible circuits connected to two or more rigid boards. They are lightweight, compact, space-efficient and best suited for medical and military applications.

High-frequency PCB

These PCBs are used in devices in the 500MHz frequency range – 2GHz. Frequency-sensitive applications such as microwave and communications systems use high-frequency PCBs.

Aluminum back PCB

These PCBs have aluminum supports for regulating heat as well as high rigidity and low thermal expansion. They are often used in high-power appliances such as leds and power supplies.

conclusion

PCBs have changed, simplifying the use of many appliances. PCBs are now ubiquitous, from desktop computers to high-end medical devices.

This method of easily interconnecting electrical components on thin, solid but optimized circuit boards has produced many appliances that are smaller, more powerful, more convenient and cheaper. Its perfect combination of materials and design makes it an ideal choice for almost any consumer or industrial device.

Effective and efficient PCB operation is supported by some amazing built-in components such as resistors. Batteries, capacitors, lights and switches control complex systems.

In addition, different types of PCBs can be molded to better meet any requirements. Different types of PCBs, such as rigid, flexible, rigid, high frequency and aluminum backing, have their own characteristics in shaping themselves to suit different devices.