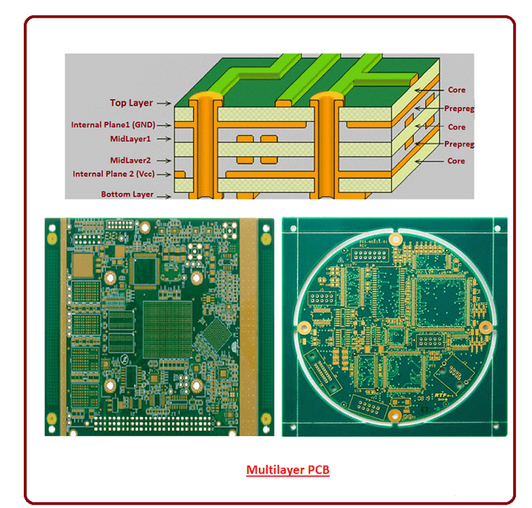

Compare multilayer PCB manufacturing with single layer PCB

With the development of technology,PCB assembly continues to develop over the years. Nowadays, multilayer PCBs allow designers and developers to integrate large, complex circuits onto a small piece of multilayer PCB.

Manufacturing multilayer PCBs involves modern tools and high precision. Compared to a single layer PCB, it is very different. The manufacturing process requires consideration of microscopic details.

Technology involved in multilayer PCB manufacturing

Multilayer PCB manufacturing involves design and development with high precision. Special attention must be paid to layers and the orientation of the paper must be accurate. The technical details of the material must be considered throughout the process.

The following are the important steps involved in the development of multilayer PCB.

Custom PCB manufacturer

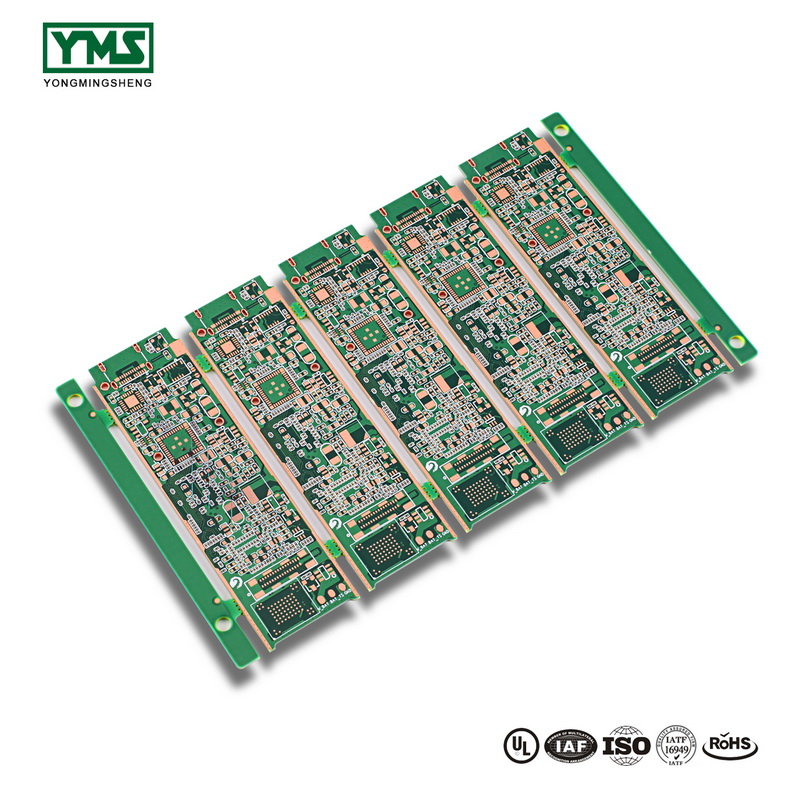

The first step is to find the right multilayer PCB manufacturer to provide custom PCB designs. Provide design requirements and functions. As low quality manufacturing will lead to poor performance and shortened PCB life, it is recommended to order only from well-known brands.

Multilayer PCB design

Multilayer PCB designs are developed through various tools and platforms such as Altium. Modern tools provide a large library of components and layout designs based on the nature of the circuit. The design of each layer must be considered in the manufacturing process. A single inappropriate through-hole placement can affect the circuit through multiple layers. Professional multilayer PCB manufacturers use advanced software programs to develop Gerber files to ensure high performance.

Electronic components

The use of high quality electronic components is critical to high quality product development. It is best if your manufacturer outsources electronic components after cross-checking your design. Using modern components instead of outdated ones can provide greater efficiency and reliability. Top manufacturers provide customers with maximum comfort and manage all components from their source. It helps to replace old/unavailable components.

How to make modern multilayer PCB

A multilayer plate consists of a continuous layer of dielectric and conductive plates connected together. Typically, fiberglass and copper plates are used in this process. Multilayer PCBs involve sensitive programs with high precision.

Multilayer PCB manufacturing process involved

The front-end engineering

Picture drawing

Imaging and development

Automatic optical detection

oxide

laminated

drilling

Electroless copper plating

Dry film outer

plate

Peel and etch

Resistance welding layer

< li> electrical test

making

Micro chip

The final inspection

How to select a multilayer PCB manufacturer

Compare multilayer PCB manufacturing with single layer PCB.

Various manufacturers provide service manufacturing for multilayer PCB. Market research must be carried out before placing an order.

Multilayer PCB design is a delicate process, and a slight oversight can lead to a poor experience. Be sure to select your manufacturer after proper research.

Consider the following factors when choosing a PCB manufacturer.

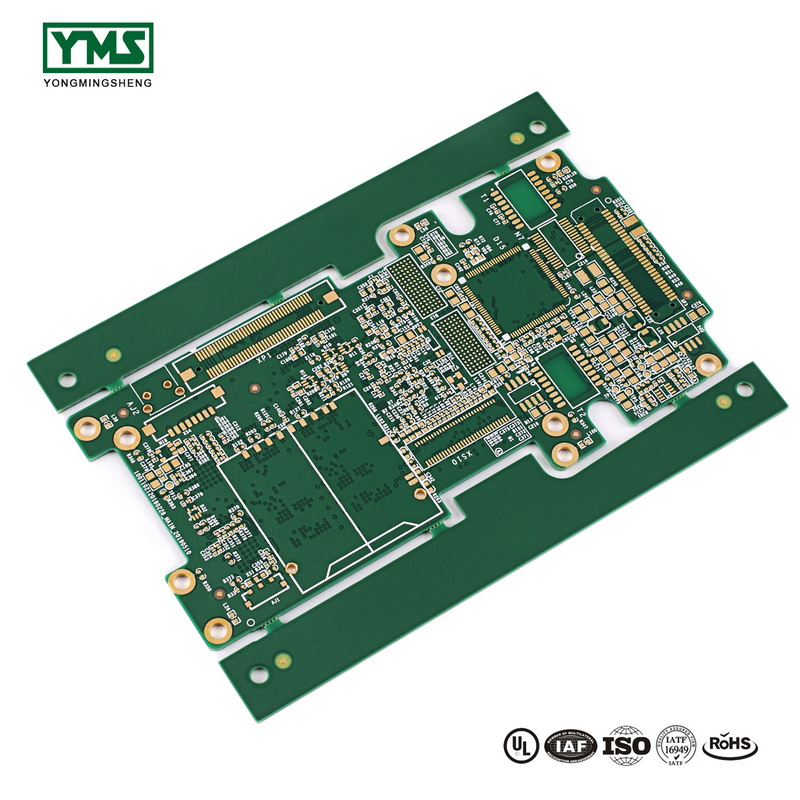

Certified manufacturer

The manufacturer must have the necessary certification for multilayer PCB manufacturing. Proper certification ensures that the manufacturer is qualified to manufacture the product.

Multi-layer PCB manufacturing in accordance with international standards can only be maintained by qualified manufacturers.

Quality assurance

PCB materials must be of high quality. Since experienced manufacturers understand the vitality of quality, they pay special attention to material quality.

In addition, quality assurance departments play a vital role in ensuring that manufactured products conform to standards. Perform multiple tests on each PCB to ensure proper operation.

Manufacturing experience

Manufacturers must have traceability experience with multilayer PCB designs. Top manufacturers always provide complete details about their experiences on their online portals.

Custom multilayer PCB designs are never recommended through inexperienced manufacturers.

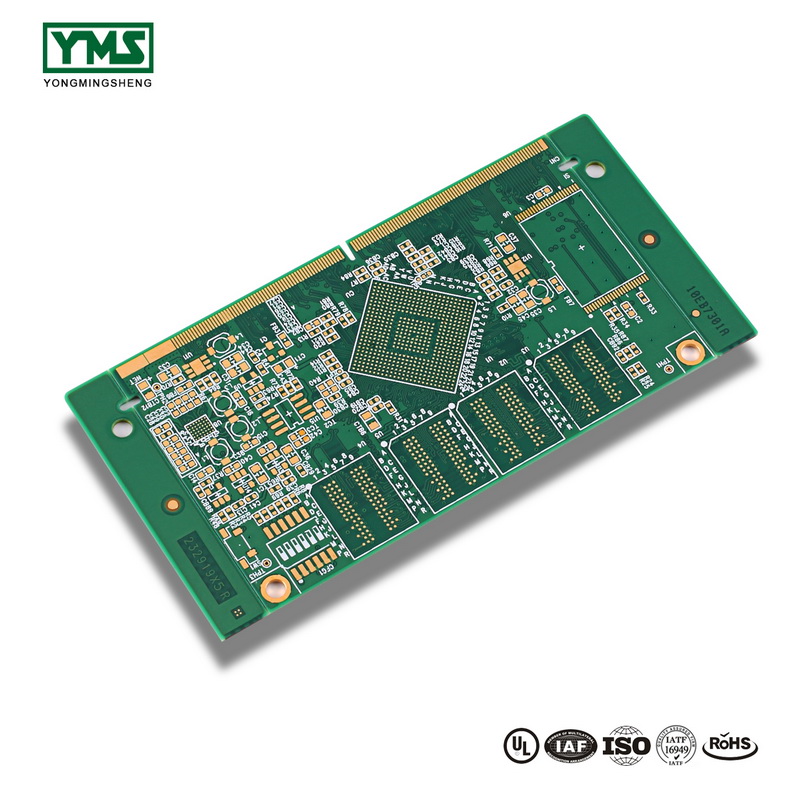

< strong> modern equipment and laboratories

The tools and software programs required for the multilayer PCB must be considered. Today, highly equipped modern CNC machines are used for multilayer PCB design.

The tools needed to test PCB quality must be modern and meet the standards defined by the part manufacturer. Traditional machines for multilayer PCB designs do not allow manufacturers to handle microscopic details.

A trusted brand

Well-known brands are based on reliability and have long been trusted by customers. Top brands pay special attention to providing reliable products within a specified time. They are more popular than inexperienced startups.

PCB test

In multilayer PCB design and development, a single misaligned connection can be destructive. Prototype design must be simulated before manufacturing to prevent any possible failures.

In addition, the manufacturer must perform the necessary tests and ensure that the PCB runs as required. Always prefer manufacturers who provide PCB testing facilities.