- Home

- News

- The comparison between aluminum PCB and copper PCB and the application of aluminum PCB in LED | YMSPCB

The comparison between aluminum PCB and copper PCB and the application of aluminum PCB in LED | YMSPCB

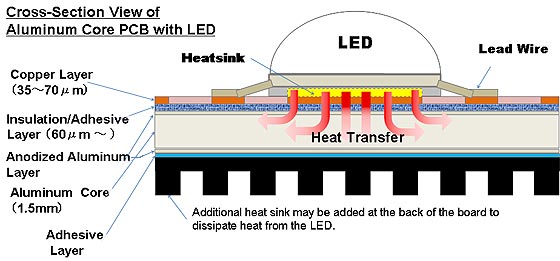

Aluminum core printed circuit boards called aluminum base baord are common in LED lighting products because of their ability to dissipate heat. Front and back have two sides. The white side is soldered to the LED pin and the other side is in aluminum form. Typically, a heat conducting paste is applied and then contacted at the heat conducting portion.

Aluminum base board is a metal base copper clad laminate with good heat dissipation function. Typically, a single-layer aluminum base board consists of three layers: a circuit layer (copper foil), an insulating layer, and a metal base.

Also used for the design of two-sided high-end applications, the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer.

Very few applications are multilayer panels, which can be composed of ordinary multilayer panels with insulation and aluminum substrates.

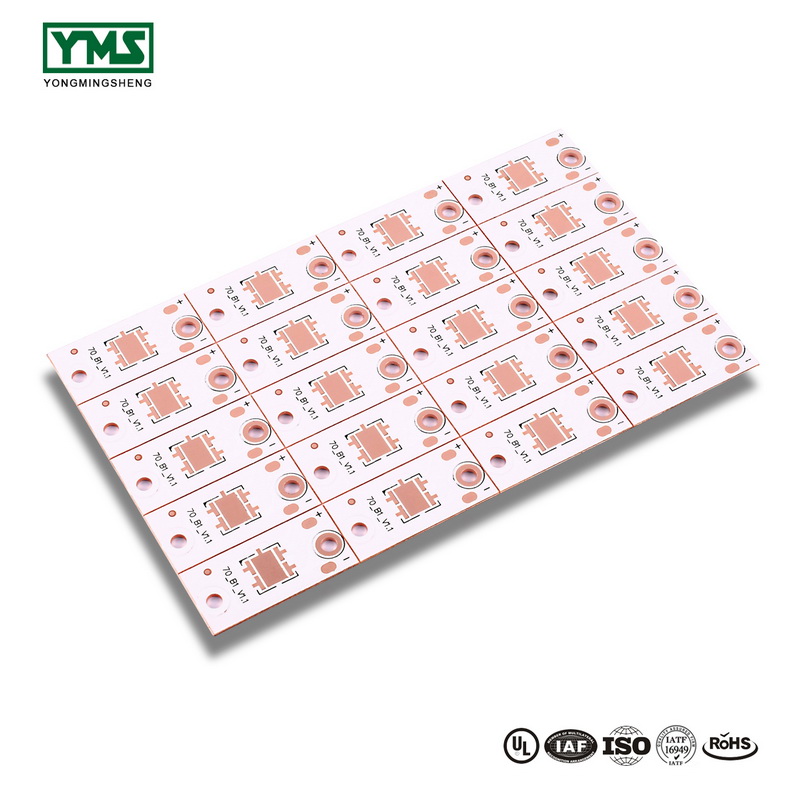

LED aluminum base board is PCB, which also means printed circuit board. The circuit board is made of aluminum alloy.

In the past, the material of our general purpose circuit board is glass fiber, but because of the LED heat is very big, the circuit board of LED lamp is generally aluminum base board which can conduct heat quickly, the circuit board of other equipment or electrical appliances is still glass fiber board!

Compared to traditional fr-4, aluminum base board can reduce the thermal resistance to a very low level (heat resistance is comprehensive) reflecting the parameters of the ability to block heat transfer.

In the application of heat transfer engineering, in order to meet the requirements of the production process, heat transfer is sometimes enhanced by reducing the thermal resistance. Sometimes increased heat resistance to inhibit heat transfer, aluminum base board has excellent thermal conductivity. Compared with thick film ceramic circuit, its mechanical properties are very excellent.

Etch circuit layers (usually using electrolytic copper foil) to form printed circuits for assembly and connection of devices. The same thickness and the same line width allow the aluminum base board to carry higher currents than traditional fr-4. Reduce product size and hardware and assembly costs. Suitable for SMT process of power component surface mount.

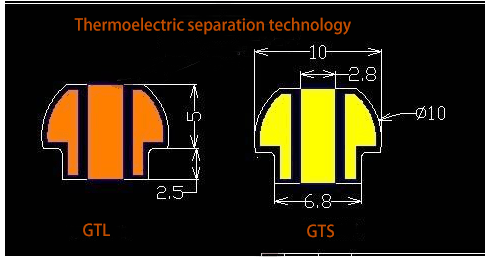

However, aluminum base board cannot be used as PTH hole. In the era of 4G network, rf signals need good grounding performance and heat dissipation requirements will be greatly improved. Aluminum base board is useless, so consider copper based board.

Copper base board

Copper base board is one of the most expensive metal base board, its thermal conductivity is many times better than aluminum base board and iron base board. Suitable for high frequency circuit and high and low temperature change area as well as precision communication equipment heat dissipation and building decoration industry.

In general, copper base board surface finished products are dipped in gold, silver, HAL, OSP, etc.

The circuit layer of copper-core PCB needs to have large carrying capacity, so thick copper foil should be used, the thickness is generally 35 microns to 280 microns. Thermal insulation layer is its core technology.

Copper base board. The core thermal module consists of a mixture of alumina and silica powder and epoxy resin. Low heat resistance (0.15), excellent viscoelasticity and heat aging. Able to withstand mechanical and thermal stress.

The metal base is the supporting component of copper-core PCB, which requires high thermal conductivity. It is usually copper base board, which is suitable for traditional mechanical drilling, punching, cutting and other processing. The metal layer (block) mainly plays the role of heat dissipation, shielding, covering or grounding.

Due to the different characteristics of copper and aluminum and the corresponding processing performance of PCB, copper base board has more performance advantages than aluminum core PCB.

Copper base has twice the thermal conductivity of aluminum. The higher the thermal conductivity, the higher the heat transfer efficiency and the better the heat dissipation performance.

2. Copper base can be machined into metallized holes, aluminum base is not allowed. The metallized mesh must be the same network, so that the signal has a good grounding performance. Secondly, the copper itself has the weldability, and finally completes the structural part of the design.Installation is optional.

The copper base of the copper base board can be etched into fine patterns and processed into the shape of the boss. The components can be directly connected to the boss to achieve good grounding and heat dissipation effect.

Due to the different modulus of elasticity between copper and aluminum (the modulus of elasticity of copper is about 121000 MPa), the corresponding warping and shrinkage of copper base board will be less than that of aluminum base board, the overall performance is better and more stability.

Rules for designing copper base board: due to the thickness of the copper base board, the minimum borehole radius must be 0.4mm. The line width is determined according to the thickness of the copper foil on the copper base board. The thicker the copper foil, the wider the thread. The minimum spacing must be larger.