What is a flex PCB

Chinese PCB manufacturer tells you

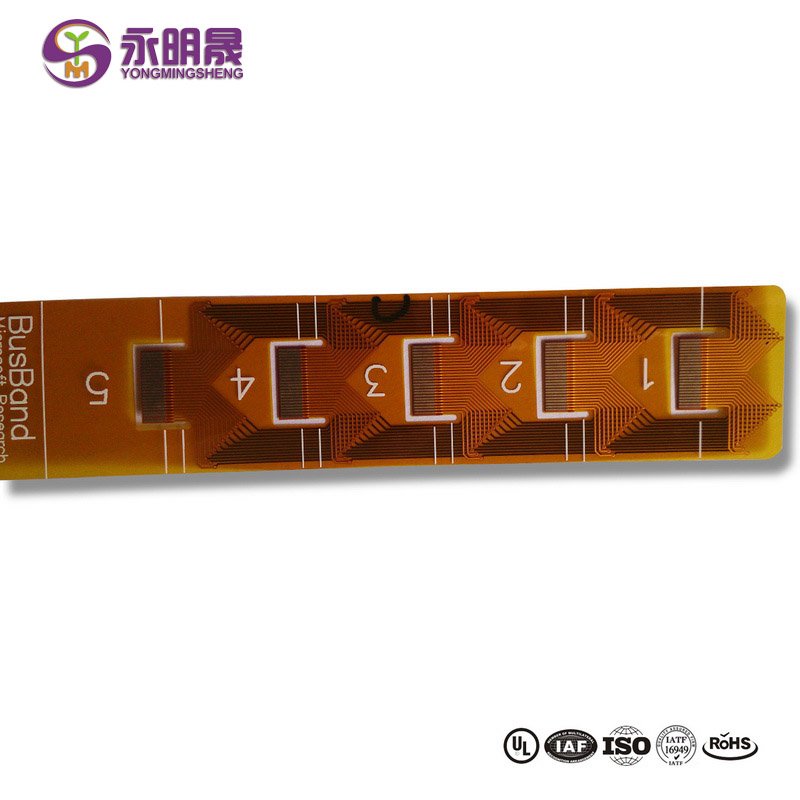

Flexible PCBs (FPC) are the PCBs that can be bent or twisted without damaging the circuits, which means the boards can be bent freely to conform to the desired shape during applications. The material the substrate used is flexible, such as Polyamide, PEEK, or a conductive polyester film.

Most of the manufacturing steps of FPCs and rigid PCBs are similar. But FPCs need some tools to hold them in a fixed position because of its flexibility.

FPCs are lighter than rigid PCBs and can be designed to smaller sizes for its flexibility. These advantages make FPCs available to replace bulky circuits in some applications. For example, FPCs can be used in Satellites, where the weight and volume are the main limitations for designers. What’s more, LED strips, consumer electronics, automobiles, and many other high-density applications favor flexible boards to reduce the size and weight.

There are no mechanical connectors in FPC applications, which improves the durability in harsh environments. And the heat dissipation ability of FPCs is better than rigid PCBs. Therefore, flexible PCBs can be found in many computer components, televisions, printers, and gaming systems.

We are a professional flex PCB & rigid-flex PCB manufacturer with guaranteed quality and fast lead-time, cooperating with worldwide customers for more than ten years in China. Please send your Gerber files to get an instant quote.

You May Like

Flexible Print Circuit 2Layer

Flex Rigid PCB PI Stiffener electromagnetic shielding film

Flexible PCB Substrate 0.10mm Ultrathin 2Layer

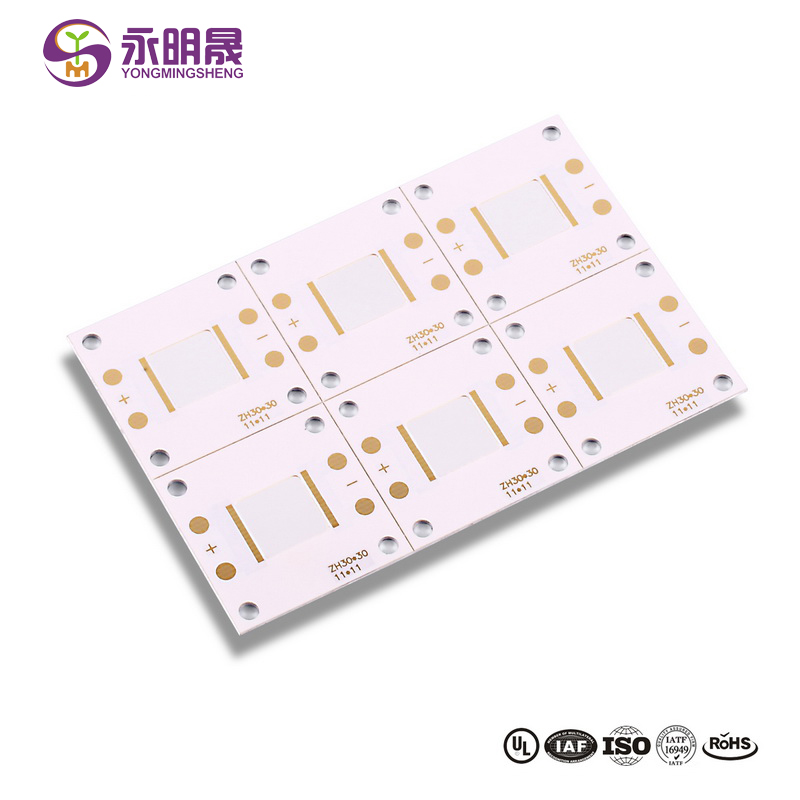

Aluminum pcbs led

People also ask

What are the materials of flexible PCB