Best-Selling Quick Turn Printed Circuit Board - Aluminum core pcb aluminum core pcb 2L aluminum pcb| YMSPCB – Yongmingsheng

Product Detail

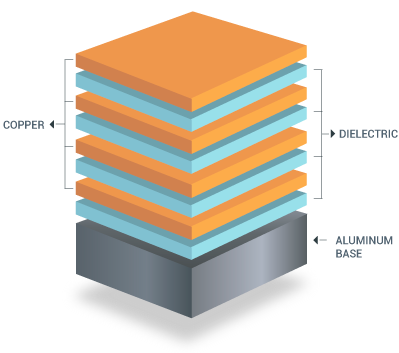

What is Multilayer Aluminum PCBs?

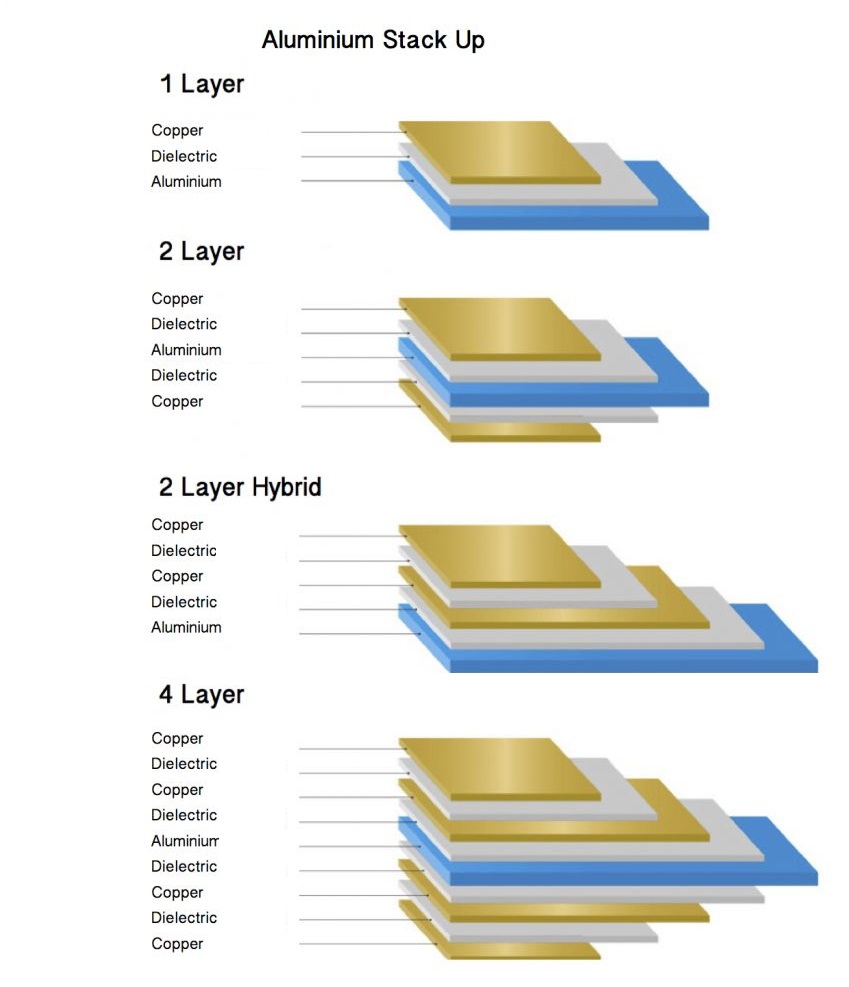

Common in the high performance power supply market, multilayer IMS PCBs are made from multiple layers of thermally conductive dielectrics. These constructions have one or more layers of circuitry buried in the dielectric with blind vias acting as either thermal vias or signal vias. While more expensive and less efficient at transferring heat as a single layer designs, they provide a simple and effective solution for heat dissipation in more complex designs.

YMS Aluminum PCB manufacturing capabilities:

| YMS Aluminum PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-4L | |

| Thermal Conductivity(w/m.k) | Aluminum PCB:0.8-10 | |

| Copper PCB:2.0-398 | ||

| Board Thickness | 0.4mm-5.0mm | |

| copper Thickness | 0.5-10OZ | |

| Minimum line Width and Space | 0.1mm/0.1mm(4mil/4mil) | |

| Speciality | Countersink,Counterbore drilling.etc. | |

| Types of Aluminum Substrates | 1000 series;5000 series;6000 series,3000 series.etc. | |

| Min mechanical Drilled Size | 0.2mm(8mil) | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

You May Like:

1、Working principle, composition and characteristics of aluminum and copper PCB

2、Application and classification of aluminum and copper base board

3、What are the requirements and specifications of aluminum PCB

Product Tags

Best-Selling Quick Turn Printed Circuit Board - Aluminum core pcb aluminum core pcb 2L aluminum pcb| YMSPCB – Yongmingsheng Related Video: