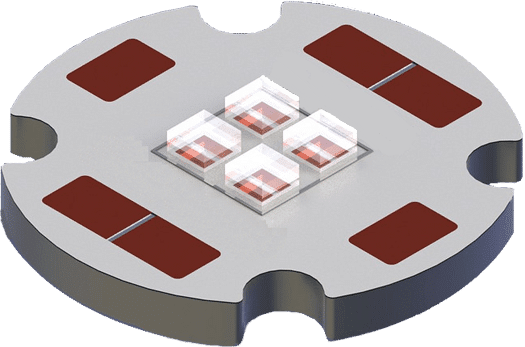

China Supplier China Single-Sided CREE LED PCB with Aluminum Material

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for China Supplier China Single-Sided CREE LED PCB with Aluminum Material, We invites you and your company to thrive together with us and share a dazzling foreseeable future in world-wide market place.

It truly is our responsibility to fulfill your requirements and successfully provide you. Your fulfillment is our best reward. We’re seeking forward in your check out for joint development for China PCB, Circuit Board, After years’ creating and developing, with the advantages of trained qualified talents and rich marketing experience, outstanding achievements were gradually made. We get good reputation from the customers due to our good items quality and fine after-sale service. We sincerely wish to create a more prosperous and flourishing future together with all the friends home and abroad!

What is Aluminum PCB?

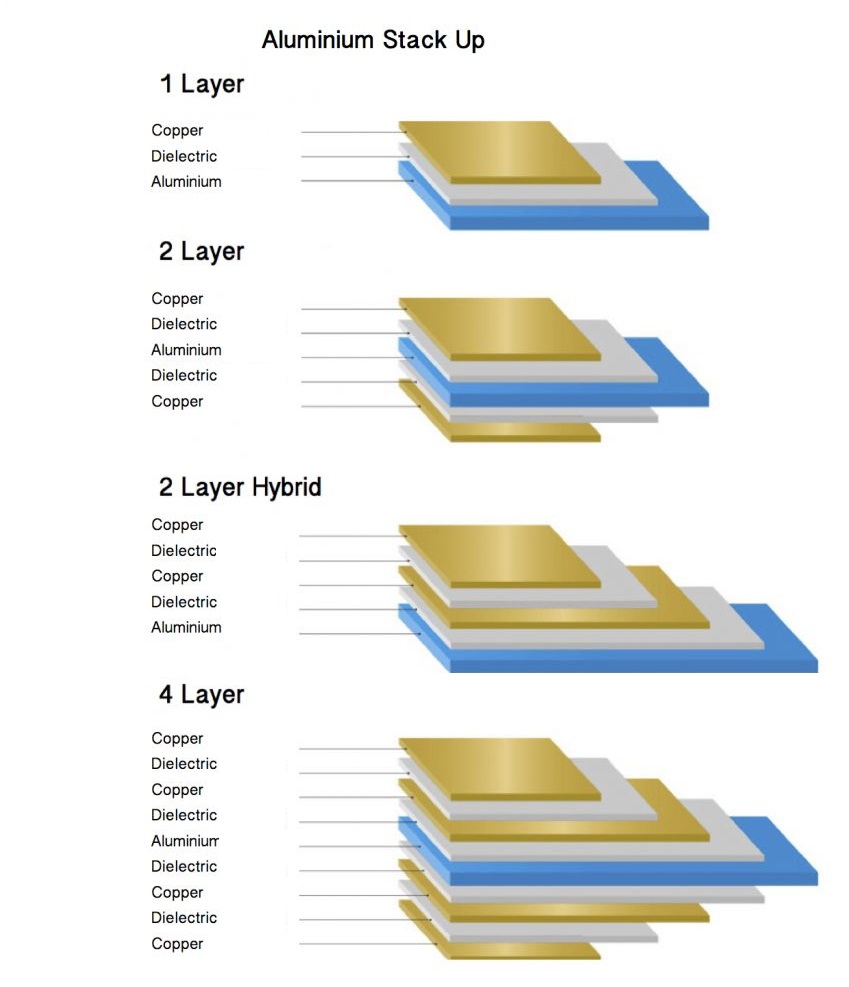

An aluminum PCB has a similar layout to Normal PCB. It has a layer or layers of copper, solder mask and silkscreen layered over it. Instead of having a fiberglass or plastic substrate, though, an aluminum circuit board has a metal substrate. This base mainly contains a combination of aluminum. The metal core can consist entirely of metal or have a combination of fiberglass and aluminum. Aluminum PCBs typically are single sided, but can be double sided as well. Mulilayer Aluminum PCBs are highly difficult to manufacture.

Performance of Aluminum PCB

1. Thermal Dissipation

Common PCB substrates, such as FR4, CEM3 are poor conductors of thermal. If the heat of electronic equipments cannot be distributed in time, it will result in high temperature failure of electronic components. Aluminum substrates can solve this thermal dissipation problem.

2. Thermal Expansion

Aluminum substrate PCB can effectively solve the thermal dissipation problem, so that the thermal expansion and contraction problem of components on printed circuit boards with different substances can be alleviated, which improves the durability and reliability of whole machine and electronic equipments. In particular, aluminum substrate can solve the SMT (surface mount technology) thermal expansion and contraction problems.

3. Dimensional Stability

Aluminum substrate printed circuit board has apparently higher stability than the insulating material of the printed circuit board. When heated from 30 ° C to 140 ~ 150 ° C, the dimensional change of aluminum substrate is only 2.5 ~ 3.0%.

4. Other Performance

Aluminum substrate printed circuit board has shielding effect, and can alternative brittle ceramic substrate. Aluminum substrate also helps to improve the heat resistance and physical properties and reduce production costs and labor.

YMS Aluminum PCB manufacturing capabilities:

| YMS Aluminum PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-4L | |

| Thermal Conductivity(w/m.k) | Aluminum PCB:0.8-10 | |

| Copper PCB:2.0-398 | ||

| Board Thickness | 0.4mm-5.0mm | |

| copper Thickness | 0.5-10OZ | |

| Minimum line Width and Space | 0.1mm/0.1mm(4mil/4mil) | |

| Speciality | Countersink,Counterbore drilling.etc. | |

| Types of Aluminum Substrates | 1000 series;5000 series;6000 series,3000 series.etc. | |

| Min mechanical Drilled Size | 0.2mm(8mil) | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

people also ask:

1.Classification and characteristics of LED aluminum pcbs substrate circuit preparation

2.Three differences between fiberglass and aluminum substrate

3.Aluminum substrate applications

4.Classification and summary of PCB aluminum substrate

5.Learn about different aluminum substrates

6.Why Can Aluminum Substrate Be So Widely Used

7.Why can’t the aluminum substrate be short-circuited

8.Aluminum Substrate Is A Composite Material Of Resin, Aluminum And Copper Foil

9.What Are The Causes Of Pcb Welding Defects On Aluminum Substrate PCB

10.How Does Led Aluminum Substrate Pcb Become The Mainstream Of Automotive Lighting Applications

11.Why Is Aluminum Pcb Used In The Circuit Board

12.Which Material Is Used In Aluminum Pcb

13.Advantages And Applications Of Aluminum Pcb

14.What Causes The Temperature Rise Of Aluminum Base Pcb

15.What Is The Difference Between Aluminum Substrate Pcb And Fiberglass

China Supplier China Single-Sided CREE LED PCB with Aluminum Material Related Video: