Factory Cheap Hot 1.2m 2layer Led Pcb - PCB Alumina,1Layer Aluminum Base Board | YMSPCB – Yongmingsheng

PCB alumina

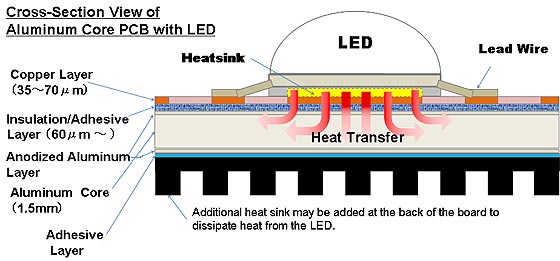

The printed circuit board made of aluminum core material is called aluminum PCB. Due to its strong cooling capacity, this circuit board is commonly used in LED lighting products.Front and back have two sides.The white side is welded to the LED pin and the other side is in aluminum form.Usually, apply a heat conducting paste and then make contact with the heat conducting part.

Aluminum substrate is a metal base clad copper laminate with good heat dissipation function.In general, single-sided aluminum PCB consists of three layers, which are the circuit layer (copper foil), the insulation layer and the metal base.Also used for high-end applications designed for both sides, the structure is circuit layer, insulation layer, aluminum base, insulation layer, circuit layer.Very few applications are multilayer panels, which can be composed of common multilayer panels combined with insulation and aluminum substrates.

LED aluminum substrate is PCB, which also means printed circuit board.The circuit board is made of aluminum alloy.In the past, the material of our general circuit board is glass fiber, but because of the LED heat is very large, LED lamp circuit board is usually aluminum substrate can be quickly heat conduction, other equipment or electrical circuit board is still glass fiber board!

Compared with the traditional fr-4, the aluminum substrate can reduce the thermal resistance to a very low level (the heat resistance is comprehensive), reflecting the parameters of the ability to block heat transfer.In the application of heat transfer engineering, in order to meet the requirements of the production process, the heat transfer is sometimes enhanced by reducing the thermal resistance.Sometimes increase thermal resistance to inhibit heat transfer), aluminum substrate has excellent thermal conductivity;Compared with the thick film ceramic circuit, its mechanical properties are very good.

Aluminum base Board production process

- Laminate Shear and drill.

- Dry or wet pattern imaging.

- Acid or alkaline etching.

- Solder mask and silk screen.

- V – CUT and final shaping

- Electrical Test and Osp

- Check up case ,packing and shipping

You May Like:

1、Working principle, composition and characteristics of aluminum and copper PCB

2、Application and classification of aluminum and copper base board

3、What are the requirements and specifications of aluminum PCB

Factory Cheap Hot 1.2m 2layer Led Pcb - PCB Alumina,1Layer Aluminum Base Board | YMSPCB – Yongmingsheng Related Video: