New Fashion Design for 3 Step Hdi Pcb - Selective Hard Gold PCB High TG FR4 Material main board| YMS PCB – Yongmingsheng

What is high Tg PCB (printed circuit board)

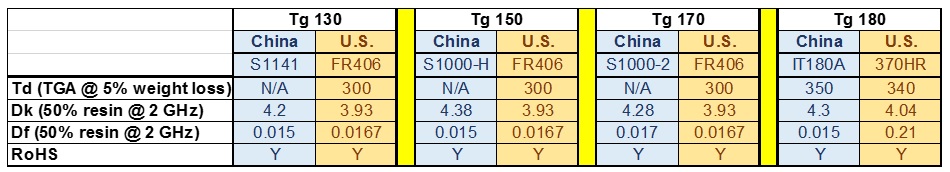

Normally high Tg refers to high heat resistance in PCB raw material, the standard Tg for copper clad laminate is between 130 – 140℃, High Tg is generally greater than 170℃, and middle Tg is generally greater than 150℃. Basically the printed circuit board with Tg≥170℃, we call high Tg PCB.

Hard Gold

▪ Usual thickness: 0.7 µm (0.00003”) to 1.3 µm (0.00005”) gold (99.7%) over 5.0

▪ µm (0.0002”) nickel or 0.2 µm (0.000008”) to 0.3 µm (0.00001”) gold (99.7%) over

▪ 5.0 µm (0.0002”) nickel for a solderable surface

▪ Very good for corrosion resistance

▪ Rated at 130-220 Knoop hardness

▪ Very good wear resistance

▪ Excellent for surface rotary switches, on-off contacts, and edge connectors

▪ Very good shelf life

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. |

|

You May Like:

1、What to do with gold finger pcb

2、Which kind of PCB board needs gold and goldfinger

New Fashion Design for 3 Step Hdi Pcb - Selective Hard Gold PCB High TG FR4 Material main board| YMS PCB – Yongmingsheng Related Video: