Multi-layer printed circuit board composition | YMSPCB

In the case of a large number of interconnection and cross requirements, PCB circuit board to achieve a satisfactory performance, it must expand the board layer to more than two layers, so there is a multi-layer PCB;

The original intention of multilayer PCB is to provide more freedom for wiring path.

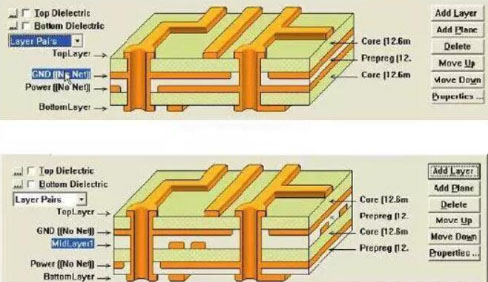

Multi-layer PCB circuit board is composed of two or more conductive layers (copper layer) superimposed on each other, and the copper layer is bonded together by resin layer (semi-curing sheet). The manufacturing process is complex, which is the most complex type of printed circuit board.

What are the basic components of multilayer PCB?

1. Signal layer

The most important way to realize information interaction of multi-layer PCB is to have three signal layers and place components and signal lines in the multi-layer PCB by means of welding, so that the multi-layer PCB can achieve the normal information service function.

Under the use of this kind of information layer, multi-layer PCB shows good information interaction ability, using this kind of multi-layer PCB can achieve better electronic control ability.

2. Internal power layer

The signal layer and the internal power layer of the multi-layer PCB are connected with each other through the aperture to achieve better electronic operation ability, while the internal power layer is a unique accessory, under the use of this internal power layer, better connection can be achieved.

3. Mechanical layer

Accessories related to plate-making and preparation method indicating information can draw the frame of the circuit board in the use of multi-layer board and place better processing technology to achieve the concise planning of the page. This mechanical layer also makes the connection of the process more clear and fast.