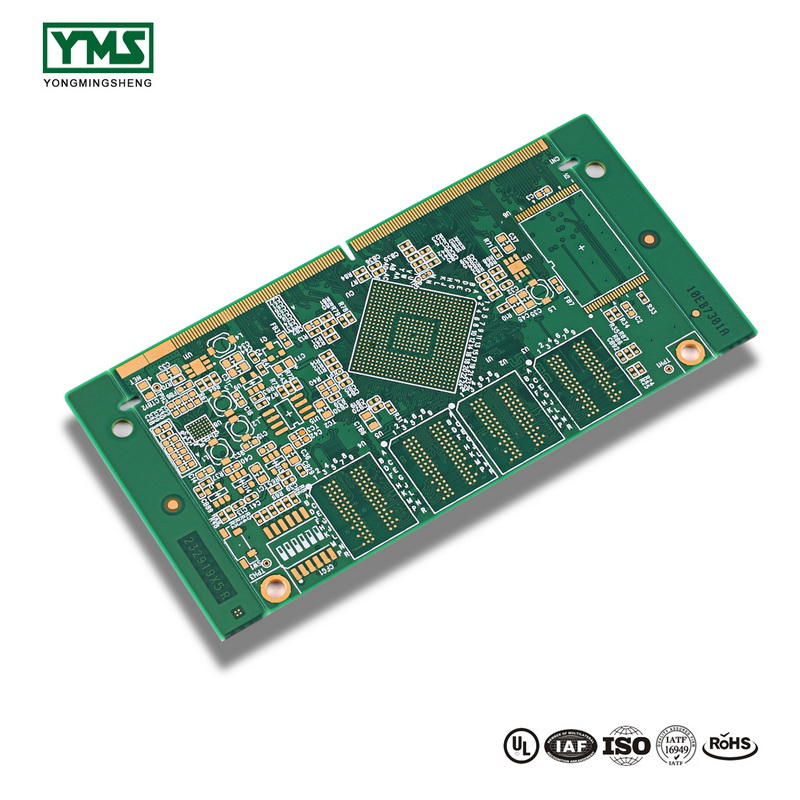

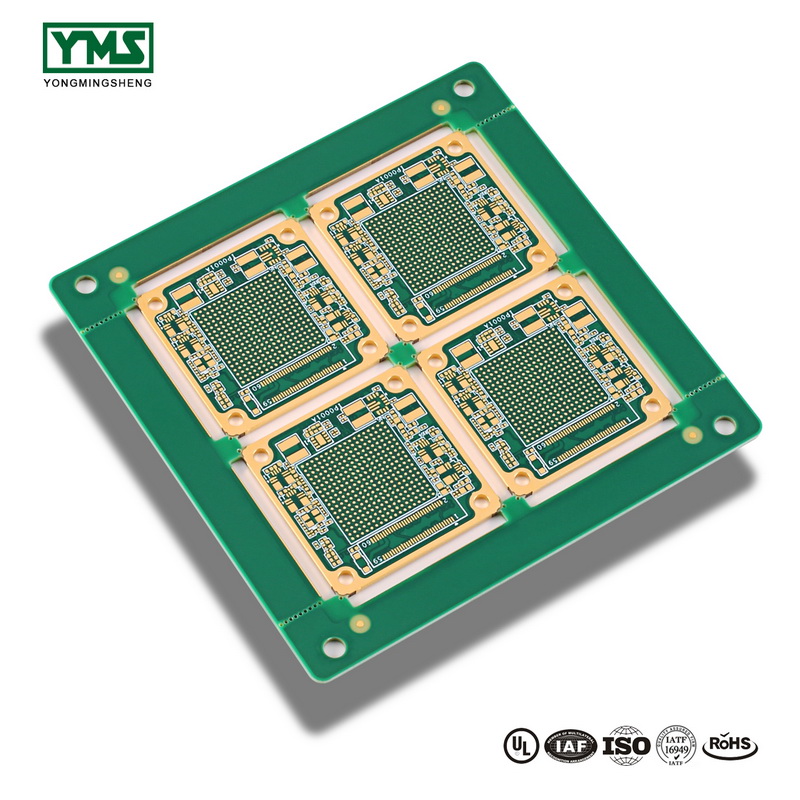

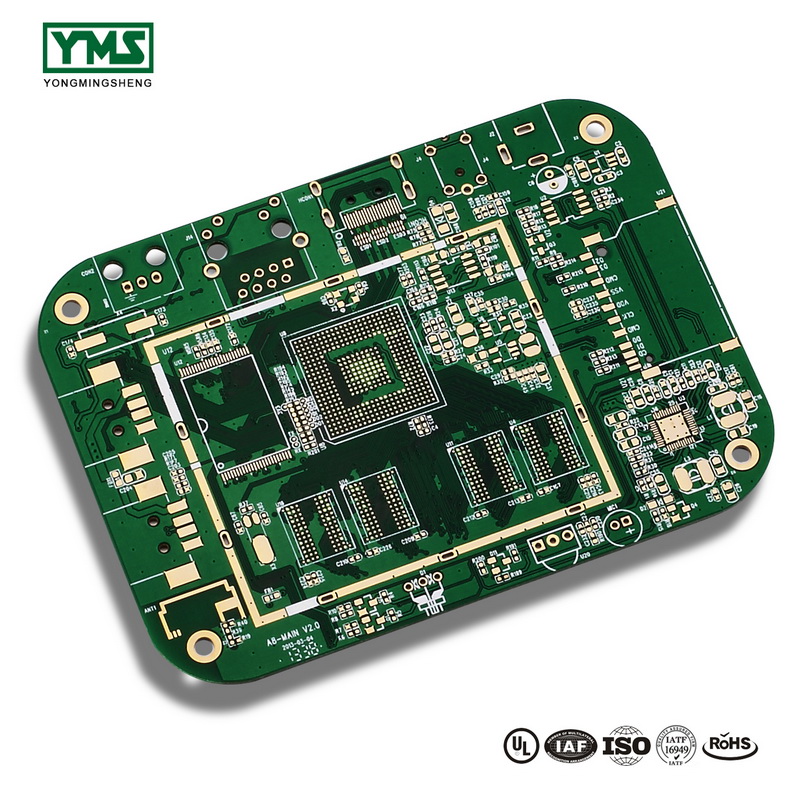

PCB processing requirements and PCB processing considerations

The process of PCB board processing requires different methods of PCB processing, and there are thousands of raw materials for PCB processing, and corresponding processing process is different, the same material with the same method processing will have a difference in order. So for professional PCB processing plant, in the face of processing methods of PCB processing have what technical requirements?

PCB processing process requirements

1. Number

The PCB should be numbered immediately after completion of processing. In order to prevent the marks from being lost in the process of processing and cleaning, the mark pen should be used to write the numbers on both sides of the board clearly. This number should be retained permanently for future management convenience.

2. Correct placement

In order to make the components surface knock scratch as little as possible, in the process of processing, transportation, and storage of PCB, it is very necessary to pay attention to handling and handling gently to prevent collision. In addition, boards need to be separated from each other to avoid mutual contact and damage to PCB.

3. PCB processing after finishing process

After the PCB is processed and tested, the whole board shall be cleaned up, including the removal of excess items on the surface such as excessive pins and metal residues. After PCB processing, the finished product should be beautified, such as hiding the front flying line as far as possible. For the back fly line is less and less, it is best to take shortcuts. The welding spot and the long flying line should be covered and fixed with the least amount of glass glue, so that it does not affect the appearance of the outside. Because for the first-class PCB processing manufacturers, whether it is internal or external is equally important. So remove excess signs, keep the color consistent and keep the PCB clean, such as dirt, clean with a brush or cotton ball.

After each piece of PCB is processed, it has to go through tedious finishing work before it can be packaged. However, the finished product received by each consumer has gone through numerous procedures without any mistakes. Every honest and reliable PCB processing manufacturers are strict execution of the above procedures, and continue to strive for perfection, just for themselves more professional, just to bring more affordable PCB processing products to consumers who trust it.

PCB processing precautions

PCB design is an important part of PCB engineer’s work. For designers, they will have a great sense of achievement if they can process their design drawings and use them successfully. PCB design is more complicated than that of other products. If a small detail goes wrong, the whole PCB board will be scrapped. PCB processing is especially important after designing. How to accurately process the PCB design drawing? PCB processing to pay attention to what matters?

For PCB engineers, they need to find a suitable PCB factory for PCB processing, and the following considerations should be taken into consideration in selecting the strength of PCB factory.

1. Factory scale

Daily production capacity of PCB factory, as well as the experience of cooperating with big brands.

2. Whether the equipment is advanced

PCB factory has stable production equipment of big brand, which is directly related to the quality of PCB.

3. Whether the process meets the design requirements

Can meet their own process requirements, such as gold process, lead spray tin, to ensure the quality of PCB board.

4. Whether the service is in place

Besides product quality, service quality is also an important factor for inspection of PCB factories. PCB factories with perfect after-sales system and strong after-sales guarantee should be selected as far as possible.

After confirming the PCB factory, submit the corresponding PCB processing documents to the factory as soon as possible.

For the PCB factory, after receiving the order of PCB processing, the first and most important step is to carefully check the PCB processing documents to avoid the subsequent processing problems caused by the initial data problems. After the process approval is completed, the process configuration is conducted with the factory.In PCB processing, PCB factory should not only ensure the quality of PCB board, but also pay attention to the delivery date. At present, customers have higher and higher requirements on delivery date, and some users require 24-hour delivery, which poses a big test to the production capacity of PCB factory and the integration ability of resources of all parties.

Huizhou Yongmingsheng Technology co., ltd. were successively established. Our enterprise is a high-tech enterprise which professional manufacture and sale high-precision single, double, multi-layer PCB, FPC, Metal PCB,Flex-Rigid Board and aluminum base board.