What is an IC substrate| YMS

Integrated circuit substrates have shot to prominence in recent times. It has resulted from the emergence of integrated circuit types such as chip-scale package (CSP) and ball grid package (BGP). Such IC packages call for novel package carriers, something that gets accounted for by IC substrate. As an electronics designer or engineer, it no longer proves sufficient to understand the importance of IC package substrate. You have to comprehend the IC substrate manufacturing process, the role substrate ICs play in the proper functioning of electronics, and its application areas. IC substrate is a type of base board used to package bare IC (integrate circuit) chip. Connecting chip and circuit board, IC belongs to an intermediate product with the following functions:

• it captures semiconductor IC chip;

• there’s routing inside to connect chip and PCB;

• it can protect, reinforce and support IC chip, providing thermal dissipation tunnel.

Attributes of an IC Substrate

Integrated circuits have numerous and diverse features. It includes the following.

Light when it comes to weight

Fewer lead wires and soldered joints

Highly reliable

Enhanced performance when other attributes such as reliability, durability, and weight get factored in

Small size What is the divination of IC substrate of PCB?

IC substrate is a type of base board used to package bare IC (integrate circuit) chip. Connecting chip and circuit board, IC belongs to an intermediate product with the following functions:

• it captures semiconductor IC chip;

• there’s routing inside to connect chip and PCB;

• it can protect, reinforce and support IC chip, providing thermal dissipation tunnel.

Applications of IC Substrate PCB

IC substrate PCBs are mainly applied on electronic products with light weight, thinness and advancing functions, such as smart phones, laptop, tablet PC and network in fields of telecommunications, medical care, industrial control, aerospace and military.

Rigid PCBs have followed through a series of innovations from multilayer PCB, traditional HDI PCBs, SLP (substrate-like PCB) to IC substrate PCBs. SLP is just a type of rigid PCBs with similar fabrication process approximately semiconductor scale.

Inspection Capability and Product Reliability Test Technology

IC substrate PCB calls for inspection equipment that is different from that used for traditional PCB. In addition, engineers have to be available that are capable of mastering inspection skills on the special equipment.

All in all, IC substrate PCB calls for more requirement than standard PCB and PCB manufacturers have to be equipped with advanced manufacturing capabilities and be proficient in mastering them. As a manufacturer with many years of PCB prototype experience and advanced production equipment, YMS can be the right partner when you run a PCB project. After providing all the files the fabrication needs, you can get your prototype boards in a week or less. Please contact us to get the best price and production time.

Video

Learn more about YMS products

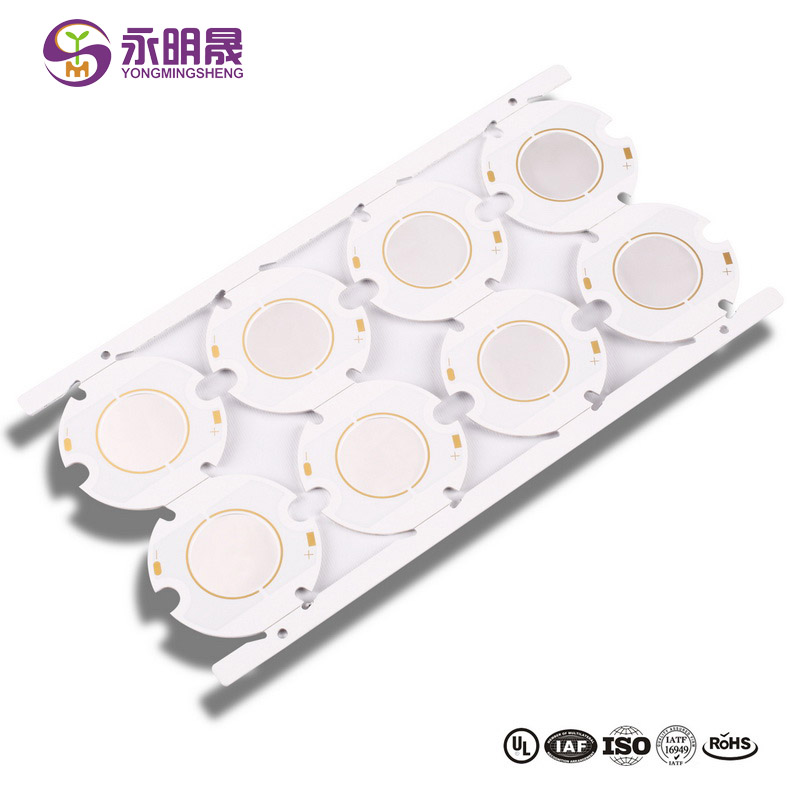

LED Aluminum pcb

1Layer White solder

Flex Rigid PCB

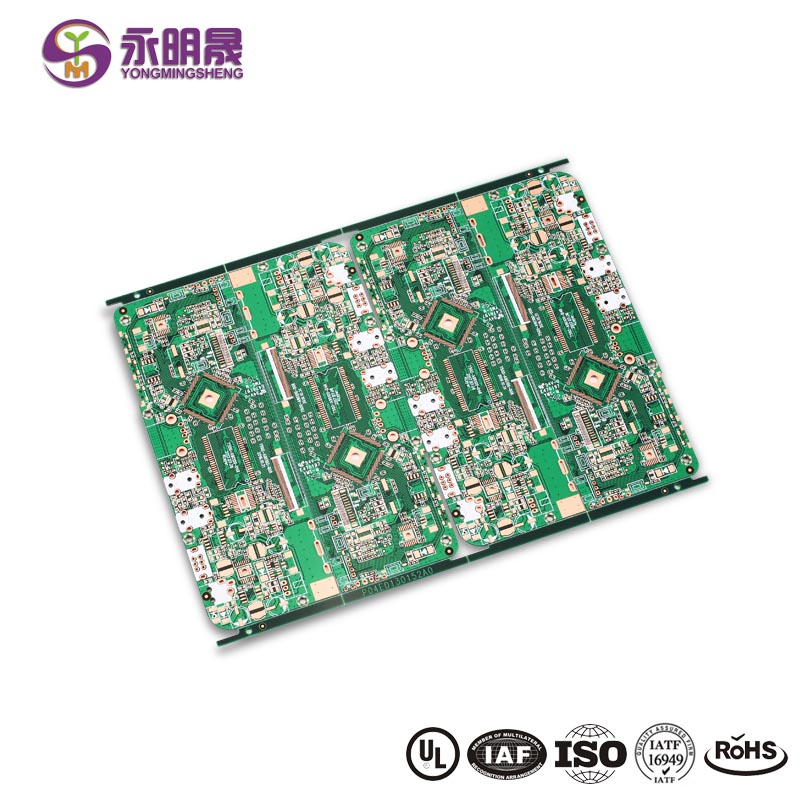

high-density multilayer pcbs

Read more news

2. What is HDI on printed circuit boards