OEM/ODM Manufacturer Cem-1 - Metal core PCB embedded copper coin pcb Thermal Management| YMSPCB – Yongmingsheng

MCPCB, Metal Core PCB, thermal PCB

In recent years, LED industry has been rapidly developed, but the problem of heat dissipation has been puzzling the application and development of LED, especially high-power LED in the field of lighting. The application of metal substrate provides a new way to solve the heat dissipation of LED effectively.

Metal core pcb is abbreviated as MCPCB, it is made of thermal insulating layer, metal plate and metal copper foil, which has special magnetic conductivity, excellent heat dissipation, high mechanical strength and good processing performance. For metal core base material, there is aluminum and copper base materials. Aluminum substrate is a kind of metal-based copper clad plate with good heat transferring and dissipation function. Copper substrate has better performance than aluminum, but its price is relatively more expensive than aluminum.

Clients order aluminum pcbs more often, because the price of aluminum pcb is much more economic, they are used for LED lighting, audio frequency apparatus and communication electronic equipment.

Mcpcb Stack UP

A simple layer single sided MCPCB consists of a metal base (usually aluminum, or copper alloy), Dielectric (non-conducting) Layer, Copper Circuit Layer, IC components and solder mask.

Single Layer MCPCB Structure

COB MCPCB, known as “Chip-On-Board” Metal Core PCB, is a type of MCPCB used in thermoelectric separation application

Two (Double) layers MCPCB is consisting of two layers of copper conductor, put them on same side of metal core (usually aluminum, copper or iron alloy).

Structure of 2L MCPCB

It also has same two layers of copper conductor like Double layers MCPCB, but the metal core is in the middle of two conductor, so there’re conductors (trace) on both sides of metal core,

and were connected to each other by Vias. So we named it “Double sided MCPCB”, and you can populated SMD on both top and bottom.

What is the PCB embedded copper coin.

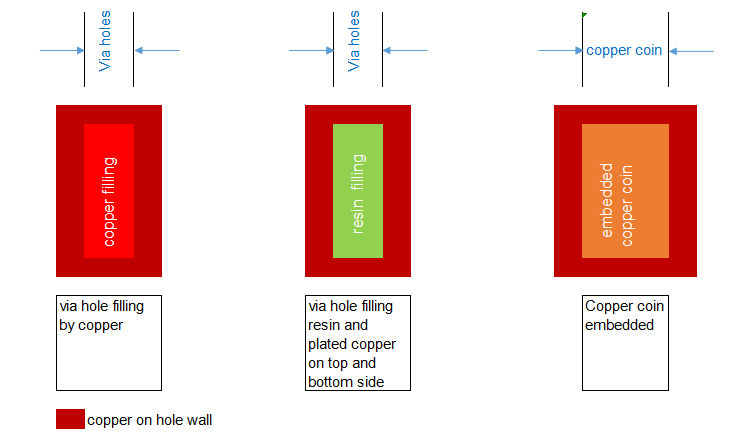

The PCB embedded copper coin is the copper coin embedded in the PCB Cavity or slot after routing and metalized when finished PCB lamination. PCB and it’s copper coin tightly connected. he traditional way to dissipate heat in a printed circuit board is through thermal vias holes. But most PCB material is not particularly good for heat transfer.On other hand, some crucial components need high performacne of heat dissipation which standard via holes can not meet.The better heat dissipation is the use of a local Cu-Coin. This can be a Bonded Cu-Coin, Press-Fit Cu-Coin or Embedded Cu-Coin.

The methods of dissipating heat for PCB

YMS Metal core PCB manufacturing capabilities:

| YMS Metal core PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-60L | |

| Available Metal core PCB Technology | Bonded Cu-Coin, Press-Fit Cu-Coin ,Embedded Cu-Coin.etc. | |

| buried and blind via,laser via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 Mix etc. | |

| High Speed Material such as M7NE and FR4 Mix etc. | ||

| Material | CEM- | CEM-1;CEM-2;CEM-4;CEM-5.etc |

| FR4 | EM827, 370HR, S1000-2, IT180A, IT158, S1000 / S1155, R1566W, EM285, TU862HF,NP170G etc. | |

| High Speed | Megtron6, Megtron4, Megtron7,TU872SLK, FR408HR,N4000-13 Series,MW4000,MW2000,TU933 etc. | |

| High Frequency | Ro3003, Ro3006, Ro4350B, Ro4360G2, Ro4835, CLTE, Genclad, RF35, FastRise27 etc. | |

| Others | Polyimide, Tk, LCP, BT, C-ply, Fradflex, Omega , ZBC2000,PEEK,PTFE,ceramic-based etc. | |

| Thickness | 0.8 mm min | |

| Coin material Thickness | 0.8-3.0mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min Copper coin’s clearance | 1.0mm min | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Laser via copper plated shut | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

OEM/ODM Manufacturer Cem-1 - Metal core PCB embedded copper coin pcb Thermal Management| YMSPCB – Yongmingsheng Related Video: