Online Exporter PCB/Circuit Board /High TG PCB with Low Price From China Factory

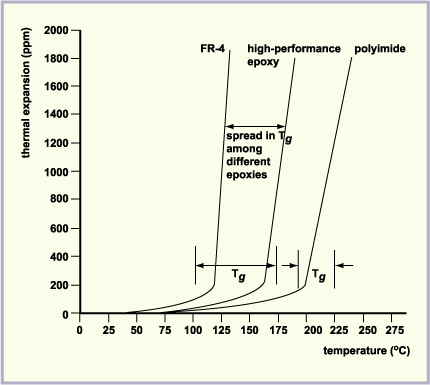

The Glass Transition Temperature (Tg) is one of the most important properties of any epoxy and is the temperature region where the polymer transitions from hard, glassy material to a soft, rubbery material.

Circuit board material must flame-resistant, it can’t be burned at a certain temperature and only be softened. The temperature point is called the glass transition temperature (Tg).

The higher Tg point means a higher temperature requirement during lamination. And the boards will be hard and crisp, which will affect the hole and the electrical properties.

A normal FR4-Tg is 130-140 degrees, the medium Tg is greater than 150-160 degrees, and high Tg is greater than 170 degrees. High-Tg FR4 will have better mechanical and chemical resistance to heat and moisture than standard FR4.

Ordinary PCB materials at high temperatures, not only will be softened, deformation, melting and other phenomena, but also the mechanical and electrical properties decline sharply.

The higher of Tg, the better the performance of PCB heat resistance, moisture resistance, chemical resistance, stability and other characteristics.

The basic meaning of high Tg PCB

FR4 is a code name for the grade of Epoxy Glass material.

Tg means Glass Transition Temperature.

When the working temperature reaches the melting point, that means the temperature exceeds the Tg value, the status of PCB material will be changed from glassy to liquid, which will affect the function of PCB. And this value is related to the stability of the PCB dimension.

As usual, made with Tg ≥ 170℃ PCB material, which is called a high Tg printed circuit board. With the rapid development of the electronics industry, high Tg material is widely used in computers, communication equipment, precise apparatus, and instruments, etc.

Check YMS High-Tg PCB manufacturing capabilities in the following table:

YMS High Tg PCB manufacturing capabilities:

|

YMS High Tg PCB manufacturing capabilities overview |

||

| Feature | capabilities | |

| Layer Count | 3-60L | |

| Available Multilayer PCB Technology | Through hole with Aspect Ratio 16:1 | |

| buried and blind via | ||

| Hybrid | High Frequency Material such as RO4350B and FR4 TG 180°Mix etc. | |

| High Speed Material such as M7NE and FR4 TG 180°Mix etc. | ||

| Thickness | 0.3mm-8mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

You May Like:

1、How to make high frequency PCB

2、Common knowledge of high frequency PCB wiring (1)

What is high Tg FR4?

The standard FR4 Tg is between 130 – 140°C, the median Tg is 150 °C and the high Tg is greater than 170°C. In the hot state, high Tg FR4 will have better mechanical and chemical resistance to heat and moisture than standard FR4.

What is TG board?

The temperature point is called the glass transition temperature (Tg). The higher Tg point means a higher temperature requirement during lamination. And the boards will be hard and crisp, which will affect the hole and the electrical properties.

How do I choose a PCB TG?

When it comes to material for PCBs, high Tg should be picked, which should be higher than the working temperature current runs. As the temperature of substance rises, substance will suffer from expansion or shrinking.

Online Exporter PCB/Circuit Board /High TG PCB with Low Price From China Factory Related Video: