PriceList for 2layer Fpc With Stiffner - Rigid flex pcb multilayer flexible pcb HDI Any-Layer PCBs stacked vias | YMSPCB – Yongmingsheng

Product Detail

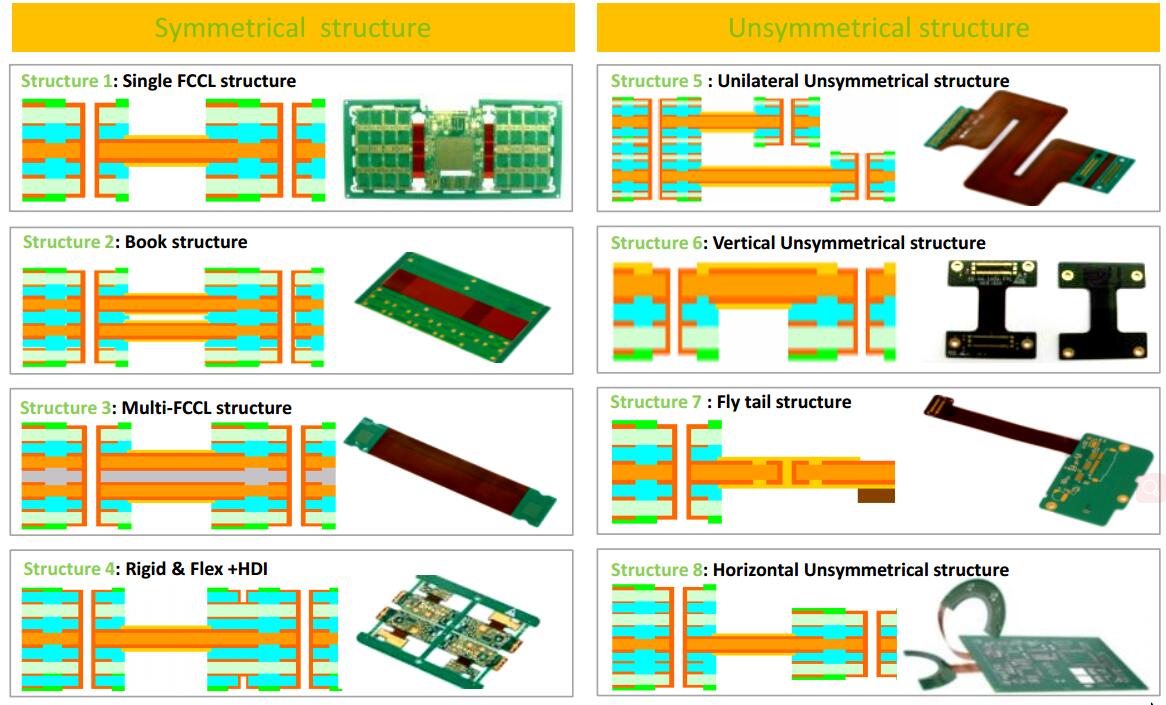

What is a Rigid Flex PCB?

Rigid-Flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application.

The proper application of Rigid-Flex circuit boards offers optimum solutions for difficult, limited space conditions. This technology offers the possibility of a secure connection of device components with the assurance of polarity and contact stability, as well as a reduction in plug and connector components.

Additional advantages of Rigid-Flex circuit boards are dynamic and mechanical stability, the resulting 3-dimensional freedom of design, simplified installation, space savings, and maintenance of uniform electrical characteristics.

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay | |

Product Tags

PriceList for 2layer Fpc With Stiffner - Rigid flex pcb multilayer flexible pcb HDI Any-Layer PCBs stacked vias | YMSPCB – Yongmingsheng Related Video: