High reputation Muti-Pcb - Double sided metal core pcb Copper Base High Power Metal core Board| YMS PCB – Yongmingsheng

What is Multi Layers MCPCB?

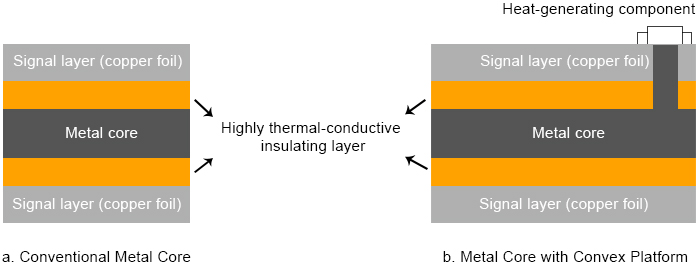

In a multilayer metal core printed circuit board (MCPCB), the layers will be evenly distributed on each side of the metal core. For instance, in a 12-layer board, the metal core will be at the center with 6 layers on the top and 6 layers at the bottom.

Metal core PCBs are classified into different types based on the number of trace layers and the location of the metal core. Two (Double) layers metal core Printed Circuit Boards have two layers of copper conductor on one side of the metal core. A two layer metal core Printed Circuit Board requires an extra step to laminate the metal core and imaged thermal conductive laminate.

YMS Multi Layers Metal core PCB manufacturing capabilities:

| YMS Multi Layers Metal core PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 1-8L | |

| Base Material | Aluminum/Copper/Iron Alloy | |

| Thickness | 0.8 mm min | |

| Coin material Thickness | 0.8-3.0mm | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| BGA PITCH | 0.35mm | |

| Min Copper coin’s clearance | 1.0mm min | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Aspect Ratio for through hole | 16:1 | |

| Surface Finish | HASL, Lead free HASL,ENIG,Immersion Tin, OSP, Immersion Silver, Gold Finger, Electroplating Hard Gold, Selective OSP,ENEPIG.etc. | |

| Via Fill Option | The via is plated and filled with either conductive or non-conductive epoxy then capped and plated over(VIPPO) | |

| Copper filled, silver filled | ||

| Registration | ±4mil | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

The main reasons for using copper base boards

1. Good heat dissipation:

At present, many 2 layer board and multilayer boards have the advantage of high density and high power, but the heat emission is difficult to be. Normal PCB base material such as FR4, CEM3 is a poor conductor of heat, insulation is between layers, and heat emission cannot go out. Local heating of electronic equipment cannot be eliminated will result in high-temperature failure of electronic components. But the good heat dissipation performance of metal core PCB can solve this heat dissipation problem.

2. Dimensional stability:

Metal core PCB is obviously much more stable in size than printed boards of insulating materials. Aluminum base board and aluminum sandwich board is heating from 30℃ to 140~150℃, its size changes of 2.5~3.0%.

3. Other cause:

Copper base board has shielding effect and replaces brittle ceramic substrate, so it can rest assured to use surface mounting technology to reduce the real effective area of PCB. Copper base board replaces the radiator and other components, improve the heat resistance and physical performance of products and it reduces production costs and labor costs.

You May Like:

1、Application characteristics of aluminum PCB

2、Copper plating process of PCB outer layer (PTH)

3、Copper clad plate and aluminum substrate four major differences

High reputation Muti-Pcb - Double sided metal core pcb Copper Base High Power Metal core Board| YMS PCB – Yongmingsheng Related Video: