Flex rigid Board 2OZ copper for flexible PCB| YMSPCB

What is a Rigid Flex PCB?

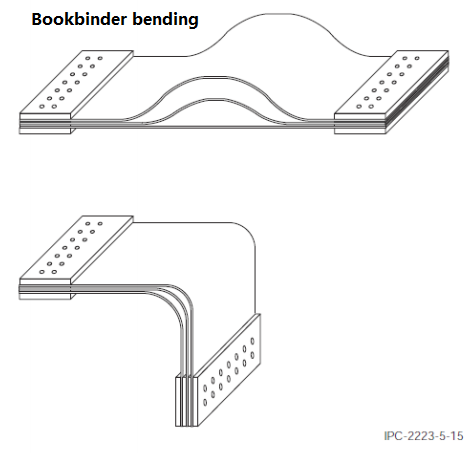

Rigid-Flex printed circuit boards are boards using a combination of flexible and rigid board technologies in an application. Most rigid flex boards consist of multiple layers of flexible circuit substrates attached to one or more rigid boards externally and/or internally, depending upon the design of the application. The flexible substrates are designed to be in a constant state of flex and are usually formed into the flexed curve during manufacturing or installation.

1. Compact size and flexible shape

Rigid-flex PCBs are easier to install more components in a smaller space because they can change the shapes according to specific outlines. This technology will reduce the size and weight of the final products and overall system costs. At the same time, the compact profile of rigid-flex PCB makes it the best choice for fine line and high-density circuits in HDI technologies.

2. Customization available for different applications

Rigid-flex PCBs are freedom in packaging geometry and can be tailored for applications in many industries such as aerospace, military, medical equipment, and consumer electrics. They are available to customize the size and shape to fit the housing designs and 3D designs, which provides designers more possibilities to meet different requirements in specific applications.

3. Better mechanical stability

The stability of rigid boards and the flexibility of flexible boards form a stable structure of the entire packages while retaining the reliability of the electrical connection and flexibility needed for installation in small spaces. 4. Better performance under harsh environments

Rigid-flex PCBs have high-shock and high-vibration resistance so that they can work well in high-stress environments. And fewer cables and connectors are used in rigid-flex PCBs, which also reduces safety risks and maintenance in future use.

5. Easy to be fabricated and tested

Rigid-flex PCBs require less number of interconnectors and related components/parts. It helps to simplify the assembly operations, making the rigid-flex PCBs are easier to be assembled and tested. Rigid-flex PCBs are very suitable for PCB Prototypes. YMS has a strict quality control system to ensure the rigid-flex boards manufactured and assembled correctly with high-quality standards. If you need more details like quotation or order, contact us via kell@ymspcb.com now.

YMS Rigid Flex PCB manufacturing capabilities:

| YMS Rigid Flex PCB manufacturing capabilities overview | ||

| Feature | capabilities | |

| Layer Count | 2-20L | |

| Rigid-Flex Thickness | 0.3mm-5.0mm | |

| PCB thickness in flex section | 0.08-0.8mm | |

| copper Thickness | 1/4OZ-10OZ | |

| Minimum line Width and Space | 0.05mm/0.05mm(2mil/2mil) | |

| Stiffeners | Stainless steel,PI, FR4 ,Aluminum etc. | |

| Material | Polyimide Flex+FR4,RA copper, HTE copper, polyimide, adhesive,Bondply | |

| Min mechanical Drilled Size | 0.15mm(6mil) | |

| Min laser Holes Size: | 0.075mm(3mil) | |

| Surface Finish | Suitable Microwave/RF PCB urface finishes: Electroless Nickel, Immersion Gold, ENEPIG, Lead free HASL,Immersion Silver.etc. | |

| Solder Mask | Green, Red, Yellow, Blue, White, Black, Purple, Matte Black, Matte green.etc. | |

| Covrelay (Flex Part) | Yellow Coverlay, WhiteCoverlay,Black Coverlay |

|

Video

Learn more about YMS products

Normal Printed Circuit Board

Multilayer PCBs 8L

Flexible Printed Circuit Board 1Layer

Flex rigid Board 2OZ copper for flexible PCB| YMSPCB Related Video: